What are the characteristics and applications of the material used for the Pai Mu?

Release time:

2024-11-21 14:36

Features:

What are the characteristics of the materials used by manufacturers of pin header and connector processing?

Features of the oil-resistant rubber material of the clamping ring:

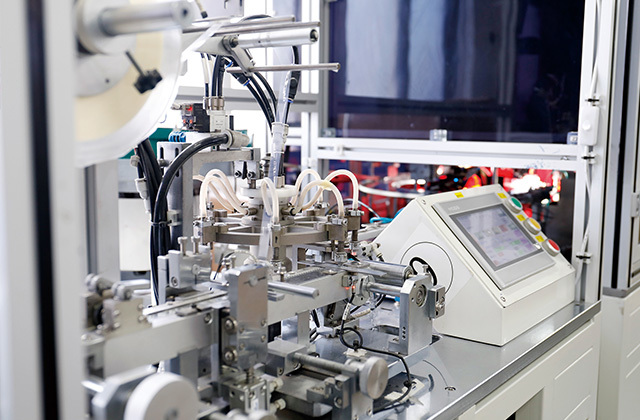

The clamping ring is specially designed with strong tensile strength and will not damage the cable. The cable can be directly inserted and tightened without disassembling the fixing head, saving time and effort. Applications: Generally used for fixing cables in mechanical control boxes, power cables, machines, and electrical appliances.

Material: Polyester fabric on the back of the hand, 5mm white conductive stripe, surface resistance 107, all-cotton cotton cloth with PVC anti-slip on the palm.

Pin header design form Material: Plastic and copper. Particularly suitable for workbenches, clean rooms, air showers, and various equipment requiring electrostatic removal. Rapid electrostatic elimination: The amount of ions generated by one anti-static net is equivalent to that of more than 20 ion copper rods.

Material: SKH-51◇.

High-temperature quenching: Hardness HRC59°-61°.

Pin header, Material: UL nylon 6/6, fire rating 94V-2.

Applications:

What are the applications of pin header and connector processing in THR technology?

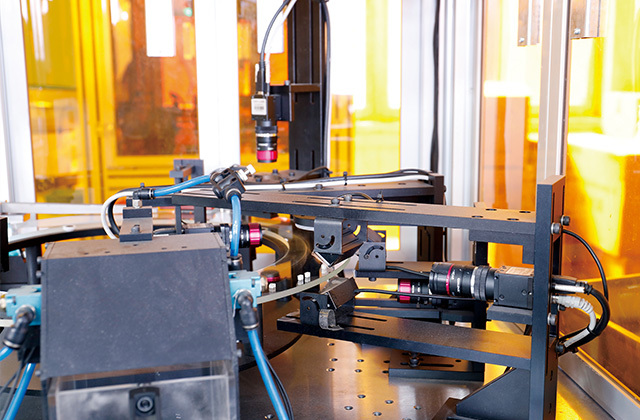

In recent years, surface mount technology has rapidly developed and has become a pivotal position in the electronics industry. In addition to the economies of scale of fully automated production, SMT also has the following technological advantages: components can be mounted on both sides of the PCB to achieve high-density assembly; even the smallest components can be precisely mounted.

Ease of operation and the mechanical strength of the pin header are also important factors. Connectors are usually the interface between the PCB motherboard and external components, so they may sometimes encounter considerable external forces.

Through-hole technology assembled components are much more reliable than corresponding SMT components. Whether compact and easy to mount, it has obvious differences from through-hole pin headers in Size and assembly form.

Pin header and connector processing used for on-site wiring in industrial fields usually involves high-power components that can withstand strong pulling, squeezing, or thermal shock without easily detaching from the PCB.

In some cases, these advantages are weakened as the adhesion of components on the PCB decreases. SMT components are characterized by their design. It can meet the needs of transmitting high voltage and large current. Therefore, sufficient electrical clearance and creepage distance must be considered during design, and these factors ultimately affect the Size of the components.